Many people have fantastic ideas for a really cool product or service they’d like to enter the marketplace with, that for some reason or another will end up making the world a better place to live. Whatever those optimistic goals may be – environmental, simplifying people’s lives (like Amazon’s one click method), improving health, or creating enjoyment, are inhibited from being accomplished because the production and manufacturing process can be downright intimidating if you’ve never played your hand in the game before. Or perhaps you are on the other side of the coin, where you are a seasoned manufacturing executive, but are looking for ways to streamline your processes in an innovative manner. Whatever your situation is, the right combination of traditional manufacturing methods combined with next-generation technological resources can result in product delivery that is faster, stronger, and better than ever before.

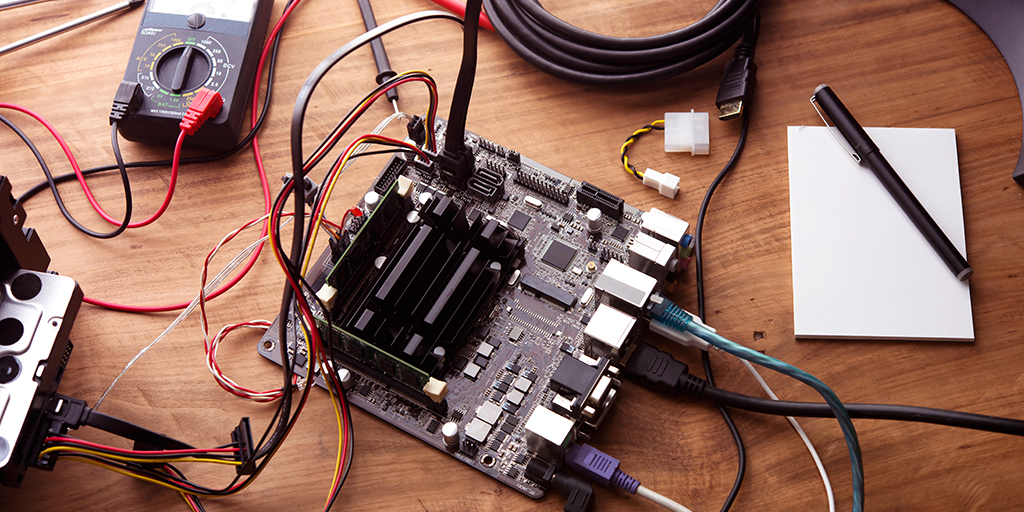

There are a lot more options out there today that increase the efficiency of the prototyping process. Sure, some of the prototypes for the best products start out with an empty toilet paper roll and some scotch tape, but that will only get you so far. Geometrical measurements, weight, and material compatibility should be more precise than what you might get with a toilet paper roll before deciding to manufacture 2000 units. Incorporating Mixed Reality into the prototyping process can be a cost saver in the end, after adding up materials, labor, and mental effort that goes into the manual construction process. Microsoft has Mixed Reality design programs that can be used with their HoloLens headgear. While wearing the headset, designers can alter their model with a swift move of their finger. The result is finding out if your idea is compatible without having to use any physical materials. Another purpose for using a MR headset is having the advantage of mobility. One can work on a project while visiting a different country, so product adjustments can be made in real-time. Many production companies have caught on to the idea of using Mixed Reality for design, and as a result are developing their own headsets and software to fit their own production needs. Some embedded technology companies are also producing headgear for Mixed Reality to be purchased for both B2B and B2C purposes. Other methods including sketching, circuit board layout & BOM documentation, and CAD (Computer Aided Design) have always proved to be beneficial towards the production process in their induvial and unique contributions. The advantage of working with a consultant is that you can relieve yourself from the responsibility of discovering and applying the appropriate methods for each individual situation. Expertise also helps during the research, design, and patent filing process, to ensure that ideas will have compatibility in the marketplace before prototype construction even begins.

Successful manufacturing consists of multiple parts, each being a vital component of the production process. Technological based concepts give the ability to provide applications including product data management, life cycle management, and CAD (Computer Aided Quality) that manage and certify that construction is occurring at the desired level of efficiency. Traditional methods applied to the manufacturing process, including activity-based and traditional manufacturing costing, lean production, and JIT (Just-in-Time) manufacturing, were invented decades ago and are still applied today because they still do an excellent job controlling costs by mitigating risk and providing some ability to forecast capital and material based needs.

However, the revelation of IoT (Internet of Things) is increasing the ability to streamline processes and cut costs more than ever before. Smart manufacturing, or building in an automated process using IoT, employs technology that gives manufacturing machinery the censored ability to adjust supply and demand without having to manage the process or report production to management in real-time. Installing IoT in an output setting results in operational efficiency, and proper energy utilization. Incorporating IoT into the manufacturing process gives any business the ability to scale so they can plan for the future with extreme precision. When hiring a consultant, make sure to choose one that has a full-spectrum of manufacturing knowledge, from traditional processes to cutting edge technology. A variety of competencies leads to the conceptualization of processes that maximize productivity because of diverse components that solutions consist of.

This article was originally published on LinkedIn: http://bit.ly/2kXLlHW

Robert Endo is the founder and Engagement Manager of Intrepid Data.

Intrepid Data is a full-service developer that builds platforms for web-based applications